Automobile Chassis Load Turning Device Exported to Vietnam

The automobile chassis load turning device we delivered to a Vietnamese car factory solves the difficulties in welding, assembly, and testing heavy chassis, ensuring safe, smooth turning and high production efficiency.

Our load turning device easily tilts a variety of heavy objects, including automobile chassis. Its innovative structural design and electric drive system enable it to reliably tilt automobile chassis from a horizontal position to the desired angle. Equipped with an advanced control system, the device ensures a smooth and safe tilting process, requiring no manual intervention. The device's size and load capacity can be customized to suit various vehicle chassis models and sizes, significantly improving production efficiency and reducing safety risks.

Customer Background and Workpiece Requirements

● Country: Vietnam

● Industry: Automobile Manufacturing

● Specific Application: Turning and positioning automobile chassis

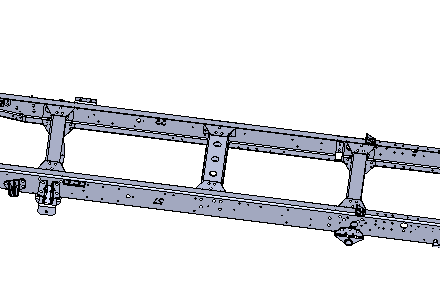

● Maximum Workpiece Dimensions: 11,000mm x 2,350mm x 500mm (various models)

● Workpiece Weight: 2,000kg - 6,000kg

● Workpiece Material: Metal

● Workpiece Description: Various vehicle chassis models

● Control Method: Push-button remote control box

● Workpiece Rotation Angle: 0° - 180°

● Drive Method: Belt Sling

Advantages of Belt Load Turning Device

● The system operates smoothly and quickly, saving time and improving production efficiency.

● Equipped with an advanced control system, the rotation angle can be precisely adjusted.

● Parameters can be adjusted to suit different load sizes and weights, making it suitable for a wide range of industries and applications.

● Multiple safety features, including overload protection and emergency stop, ensure a safe turning process.

● The belt drive offers low friction loss and high transmission efficiency, making it suitable for long-term continuous operation.

Project Results and Benefits

● Improved Efficiency: The turnaround cycle for a single piece has been reduced from 4–6 minutes to ≤2 minutes, significantly improving production line cycle time.

● Quality Assurance: The use of belt drive protection significantly reduces surface scratches on workpieces.

● Improved Safety: Multiple limit switches and overload protection reduce operational risks and worker workload.

● Automation Integration: Linked to the production line PLC, it enables cycle synchronization and remote status monitoring.

If you are looking for an efficient, safe, and reliable load turning device, please contact us for a customized solution and a reasonable quote!