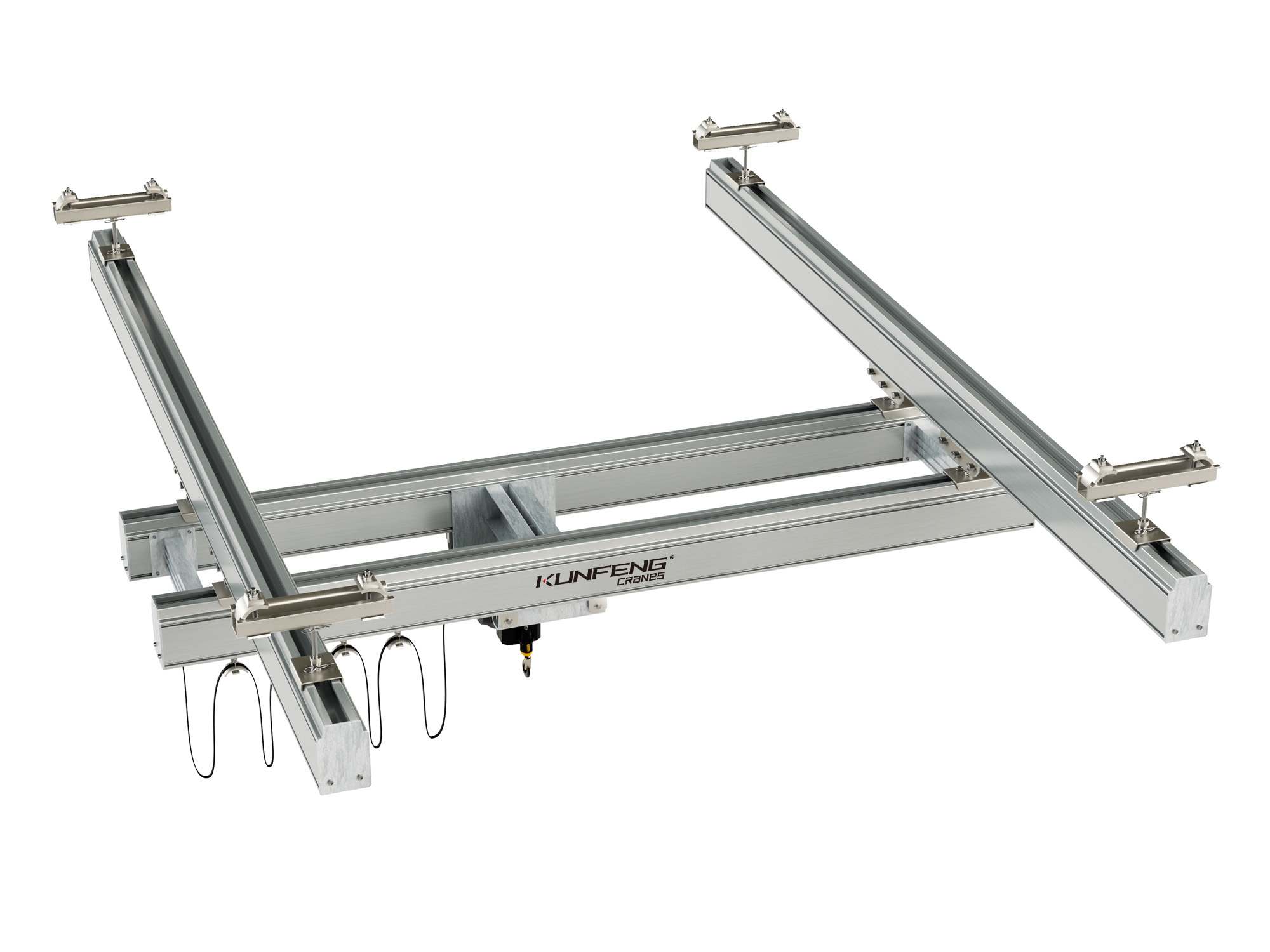

Light Crane System

The low headroom light crane system is designed for factory clearance-constrained scenarios. It supports modular rails and customized installation, facilitating workshop transformation and flexible production line upgrades.

Product Description

The low headroom light suspension crane system is an efficient material handling solution designed for factories with limited headroom, compact production lines, or clean environments. This system utilizes compact aluminum alloy or steel tracks and a light bridge. The suspended layout minimizes headroom under building beams while ensuring stable lifting and traversing. This allows for rapid deployment of lifting capacity without structural modifications.

Common Technical Parameters (Support customization)

● Rated Lifting Capacity: 150kg - 2000kg

● Span: 2m - 20m

● Lifting Height: 2m - 6m

● Operation Mode: Manual / Electric Travel

● Travel Speed: 1m - 3m/min

● Lifting Device: Fiber Rope / Wire Rope / Chain Hoists

● Track Material: Aluminum Alloy or Steel Enclosed Rail

Key Advantages of the Light Suspension Crane System

● The suspended track and compact travel mechanism minimize the vertical space occupied by the crane, making it suitable for factories with limited headroom.

● The modular design supports various track layouts, including straight, curved, and branch tracks, easily covering the entire work area.

● Available in two installation options: ceiling-mounted or floor-supported, shortening lead times and retrofit costs.

● The low headroom design shortens the distance from the hook to the main beam, reducing load swing during operation and ensuring smoother operation.

● It can be used with belt hoists, chain hoists, or small wire rope hoists to meet varying cleanliness and load requirements.

Typical Applications

● Loading and unloading materials and workstation handling on assembly lines with limited headroom

● Local lifting and material handling in cleanrooms

● Repair, disassembly, and assembly in equipment repair shops

● Upgrading and renovating production lines in existing low-rise buildings and older workshops

The light suspension crane system is a cost-effective solution for material handling in headroom-constrained conditions. For a free preliminary selection and engineering evaluation, please contact our technical team (sale@kfqizhongji.com) for a customized solution and quote.