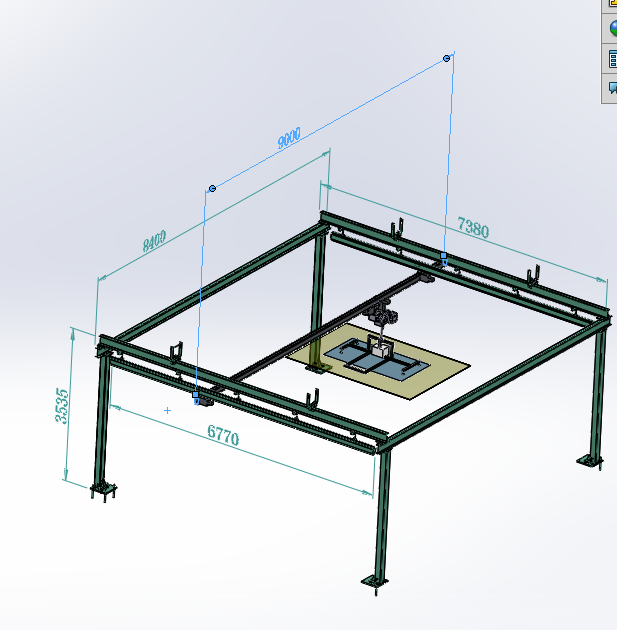

Light Crane System

The KBK light bridge crane system adopts modular steel structure and lightweight design, easy to install, flexible in layout, and supports customized span and load. It is an ideal choice for workshop production line workstations.

Product Description

The KBK steel light bridge crane system is a modular lifting solution for modern production line and workstation handling. Combining the flexible layout of the KBK system with the load capacity of a steel bridge crane, it meets the rapid deployment requirements of assembly lines and maintenance stations while providing stable, durable lifting and operating performance, making it an ideal choice for small and medium-sized workshops and production lines.

How the KBK Crane System Works

The main beam is connected to the track via end beams, which are then fixed to the factory roof or supporting structure. The hoist trolley operates on the main beam, lifting and lowering loads using manual chain links or electric chain hoists. The entire system creates a three-dimensional handling space that covers the entire work area and allows for precise positioning.

Complete Components of the KBK Light Bridge Crane System

Track System: Utilizing high-strength, lightweight cold-rolled steel tracks, ensures the system's lightweight and high rigidity.

Suspension System: Securely secures the entire track system to the factory building structure and can be flexibly adjusted to meet site conditions.

Traveling Mechanism: Includes end beams at both ends of the main beam and a lifting trolley.

Hoisting Mechanism: Can be configured with a manual hoist or electric chain hoist as needed to enable vertical lifting of cargo.

Accessories: Such as connectors, fasteners, limiters, and brakes ensure safe transportation between workstations.

Product Features of KBK Light Bridge Cranes

Standardized rails and connectors facilitate quick on-site assembly, disassembly, and expansion.

Supports various layout configurations, including single-span, multi-span, corner, and circular, meeting the needs of complex workshop layouts.

Precision rails and traveling mechanism ensure smooth lifting.

Due to the KBK system's inherent light weight, the load requirements on the factory roof structure are much lower than those of traditional cranes.

Standardized components make installation quick and easy, significantly shortening the construction period.

KBK System Applicable Industries

Automotive assembly lines

Electronic product assembly lines

Packaging and logistics centers

Machining workshops

Chemical, food, and pharmaceutical industries

KFCRANES offers one-stop, customized services, from solution design and component supply to installation and commissioning, tailored to specific customer needs.