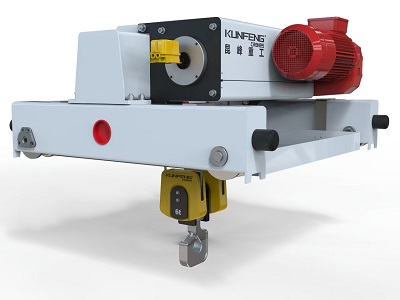

Hoists

The electric belt hoist uses high-strength fiber belts and an oil-free design. It is low in particles and easy to clean. It is designed for lifting and handling materials in clean environments such as pharmaceuticals, electronics, and food.

Product Description

Cleanroom electric belt hoist is designed for material lifting in production environments requiring extremely high cleanliness, such as pharmaceuticals, electronics, food, and biotechnology. They utilize high-strength synthetic fiber belts instead of wire ropes or chains. Their oil-free design and enclosed structure deliver stable lifting with low particle count, oil-free operation, and low noise levels. This significantly reduces the risk of contamination to the cleanroom environment, improving production line reliability and process yield.

Outstanding Features of Electric Belt Hoist

● Fiber belts require no traditional lubricants, generating no oil mist or metal particles, thus minimizing the risk of contamination.

● Specialized belts are treated with anti-static treatment to prevent the absorption of airborne particles and damage to electrostatically sensitive components.

● The hoist body is typically constructed of 304 or 304L stainless steel, with a polished surface for a smooth, seamless finish.

● Fiber belts are standard spare parts for quick replacement, and their oil-free design reduces daily cleaning and maintenance.

● Integrated with variable frequency control technology, they deliver smooth soft starts and stops, ensuring precise positioning.

Typical Application Scenarios

● Pharmaceutical Cleanrooms: Raw material loading and unloading, finished product transfer, and aseptic area handling

● Semiconductor and Electronics Factories: Particle-sensitive device assembly and loading and unloading

● Food and Beverage Production: Oil-free, contamination-free filling and packaging loading and unloading

● Laboratories and R&D Lines: Precision workstations with small batches and frequent handling

Advantages of Choosing Us

● From materials to electrical seals, all optimized for cleanroom requirements.

● Customizable to each customer's operating conditions.

● No-load and full-load test and performance test reports are provided.

● On-site installation and commissioning, operator training, and maintenance manuals are provided.

Looking for a customized, contamination-free, highly reliable upgrade solution for your cleanroom? Contact our team of professional engineers for free technical consultation and a customized solution.