Installation of Aluminum Alloy Folding Mini Gantry Crane

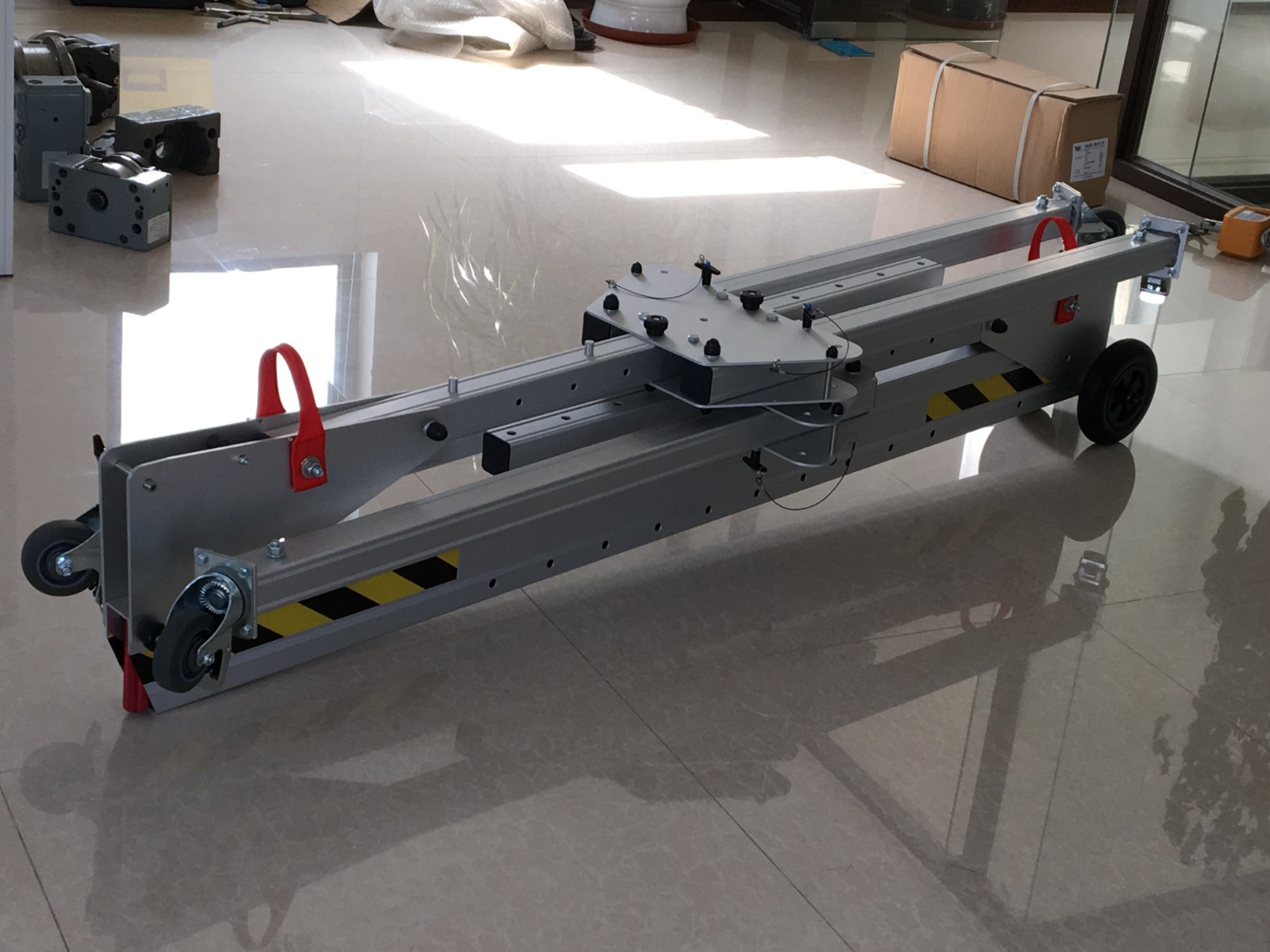

The aluminum alloy foldable mini gantry crane is an ideal equipment for rapid deployment and flexible handling due to its light weight, portability and foldable storage.

In a variety of temporary operations, limited space or light and medium load lifting environments, the aluminum alloy folding mini gantry crane has become an ideal equipment for rapid deployment and flexible handling due to its lightweight, portability and foldable storage characteristics. Compared with traditional steel gantry cranes, it has the advantages of corrosion resistance and easy handling, but to achieve its best performance, standardized installation procedures and detailed safety inspections are essential.

Main Features of Aluminum Folding Gantry Crane

● Lightweight material: The main beam and column are made of aviation-grade aluminum alloy profiles, which are much lighter than traditional steel structures, making them easy to carry by manual or small equipment.

● Folding design: Through hinges, latches or quick-release mechanisms, it can be folded and stored when not in use, saving storage space and facilitating rapid transfer between different sites.

● Modular components: The main beam, column, cross brace, base or caster and other components are standardized in design and assembled on site according to modules without welding.

● Adjustability: The height can be quickly adjusted within the design range to meet different net height and span requirements; it can be equipped with a variety of lifting mechanisms (manual/electric hoists, balance cranes, etc.).

Installation Process of Aluminum Alloy Folding Gantry Crane

● Site preparation: Measure the clearance height and ground flatness, clean the installation area and confirm that the ground load-bearing capacity meets the equipment and maximum load requirements;

● Base installation: Fix the casters or adjustable support feet to the bottom of the column, initially adjust to the same height to ensure stability;

● Column erection: Multiple people or with the help of tools, erect the folding column, use a level or plumb line to correct the verticality, and temporarily fix it;

● Main beam in place: Lift the aluminum alloy main beam to the top interface of the two columns in the folded state, insert the pin or tighten the bolt and lock it according to the specified torque, and confirm that the folding hinge has been Lock the unfolded state;

● Horizontal bracing and reinforcement: Install horizontal bracing or diagonal bracing according to the design to improve lateral stability, and check the pre-tightening of the connectors;

● Hoisting mechanism installation: Hang the manual or electric hoist to the slide rail/interface under the main beam, arrange and fix the cable or busbar, and check the smooth operation;

● Leveling and fine-tuning: Use a level to fine-tune the main beam horizontally and vertically to ensure that the horizontality and column verticality are within the allowable range;

● Functional test: First perform no-load lifting and walking tests, then perform static and dynamic tests according to the rated load to verify that the limit, overload protection and emergency stop devices can all operate normally.

Solutions to Common Installation Problems

● Uneven ground/inadequate locking causes leg shaking, you can pad steel plates/readjust telescopic sleeves

● The main beam joint is misaligned due to the failure to tighten the bolts diagonally, you can loosen them and tighten them in sequence

● Impurities in the track cause the pulley to get stuck, you can clean it again and apply grease

Through the above practical guidance, from preliminary preparation to commissioning acceptance to daily maintenance, you can efficiently and safely complete the deployment and use of aluminum alloy folding gantry cranes, providing reliable lifting support for production or operation scenarios. If you have more needs or questions, it is recommended to contact our technical team to customize the optimization plan based on the on-site conditions to achieve the best results.