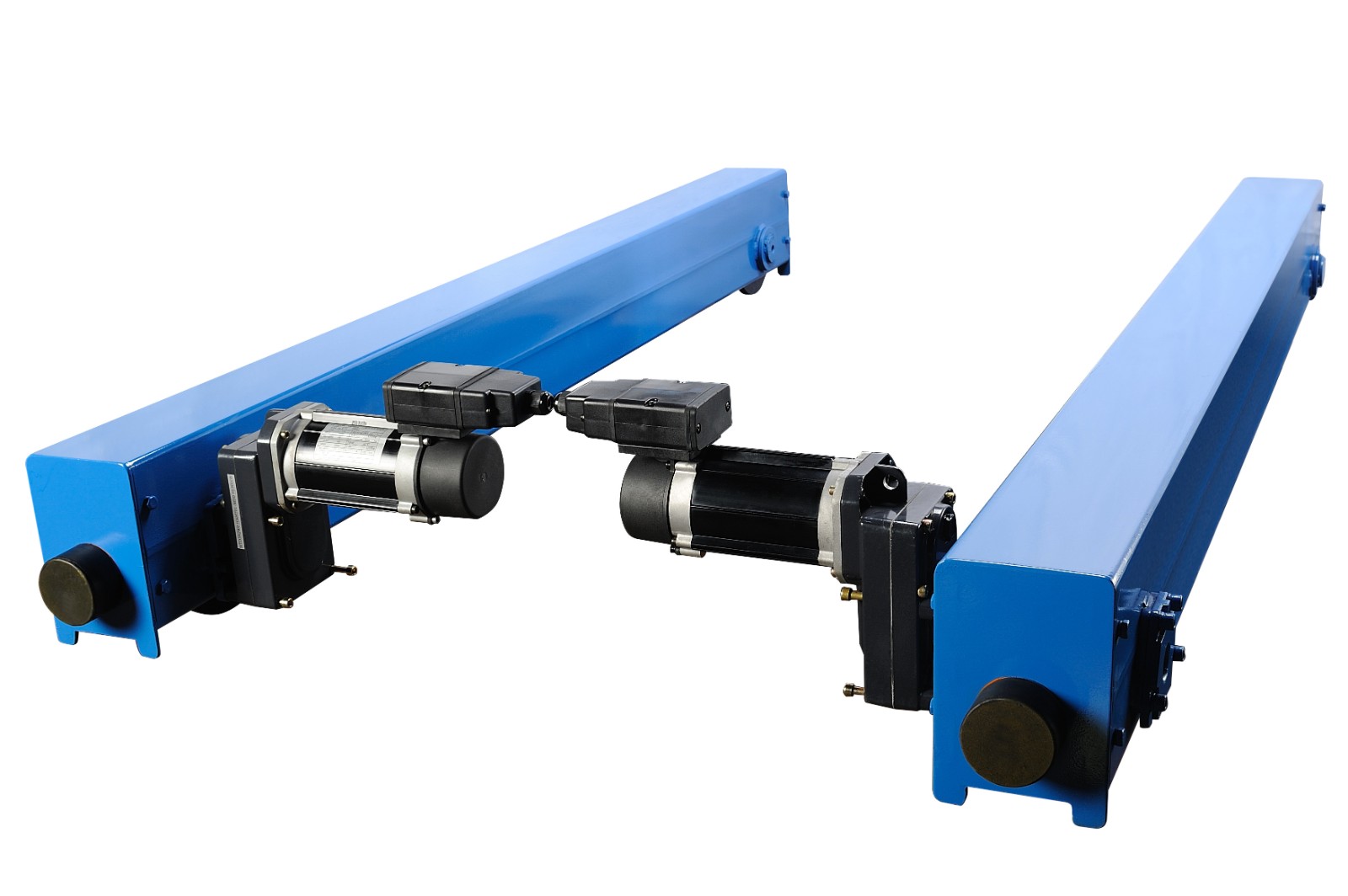

Components

Overhead crane end trucks are key components for the smooth operation of cranes. They support customized designs, have a sturdy structure, and are easy to install. They are suitable for a variety of industrial lifting applications.

Product Description

End trucks for overhead cranes are the key load-bearing components connecting the crane main beam and the wheel group. They are responsible for supporting the full load of the bridge and transferring the load evenly to the track. End trucks are well designed and well manufactured, and are an important part of ensuring the smooth and safe operation of the crane.

Main Features of Crane End Trucks

● Made of high-quality carbon steel or alloy steel, normalized or annealed to ensure good tensile and fatigue resistance.

● The cross-section is optimized through finite element analysis to fully reduce its own weight while ensuring that the strength and rigidity meet the heavy-load performance requirements.

● The end carriage structure is CNC cut, bent and welded, and the surface is rust-removed, sandblasted and anti-corrosion painted. The dimensional tolerance is strictly controlled, which is convenient for rapid installation and docking on site.

● We provide a variety of end carriages and main beam connection solutions such as welding type, bolt connection type, and plug-in type, which can be flexibly selected according to user needs and site conditions.

● Standard double-rim cast steel wheels (polyurethane rubber wheels are optional).

● Support customization of end carriages with different spans, lifting weights, and walking methods to meet the diverse working conditions of bridge cranes.

Main Technical Parameters (For Reference)

● Material: Carbon steel / Alloy steel

● Applicable tonnage: 1t - 100t

● End beam height: 400 - 1800mm

● Wheel diameter: Φ300-Φ900mm

● Surface treatment: Sandblasting and rust removal + painting

● Connection method: Welding / Bolt / Plug-in

● Working level: A3-A7

Customized Service

● Structural design: Provide end carriages structural optimization design according to on-site track gauge, span and operation requirements.

● Welding and processing: Hold a national welder certificate and use automated welding technology to ensure weld quality.

● Anti-corrosion and coating: Multi-layer anti-rust primer + topcoat process to adapt to different environments.

● Installation guidance: A professional engineer team provides installation, commissioning and acceptance services to ensure seamless connection between end carriages and main beams.

Choosing high-quality end trucks for overhead cranes can significantly improve the structural strength and operating stability of the overall crane system. If you need to learn more about the product details or request a customized solution, please contact our technical team (sale@kfqizhongji.com).